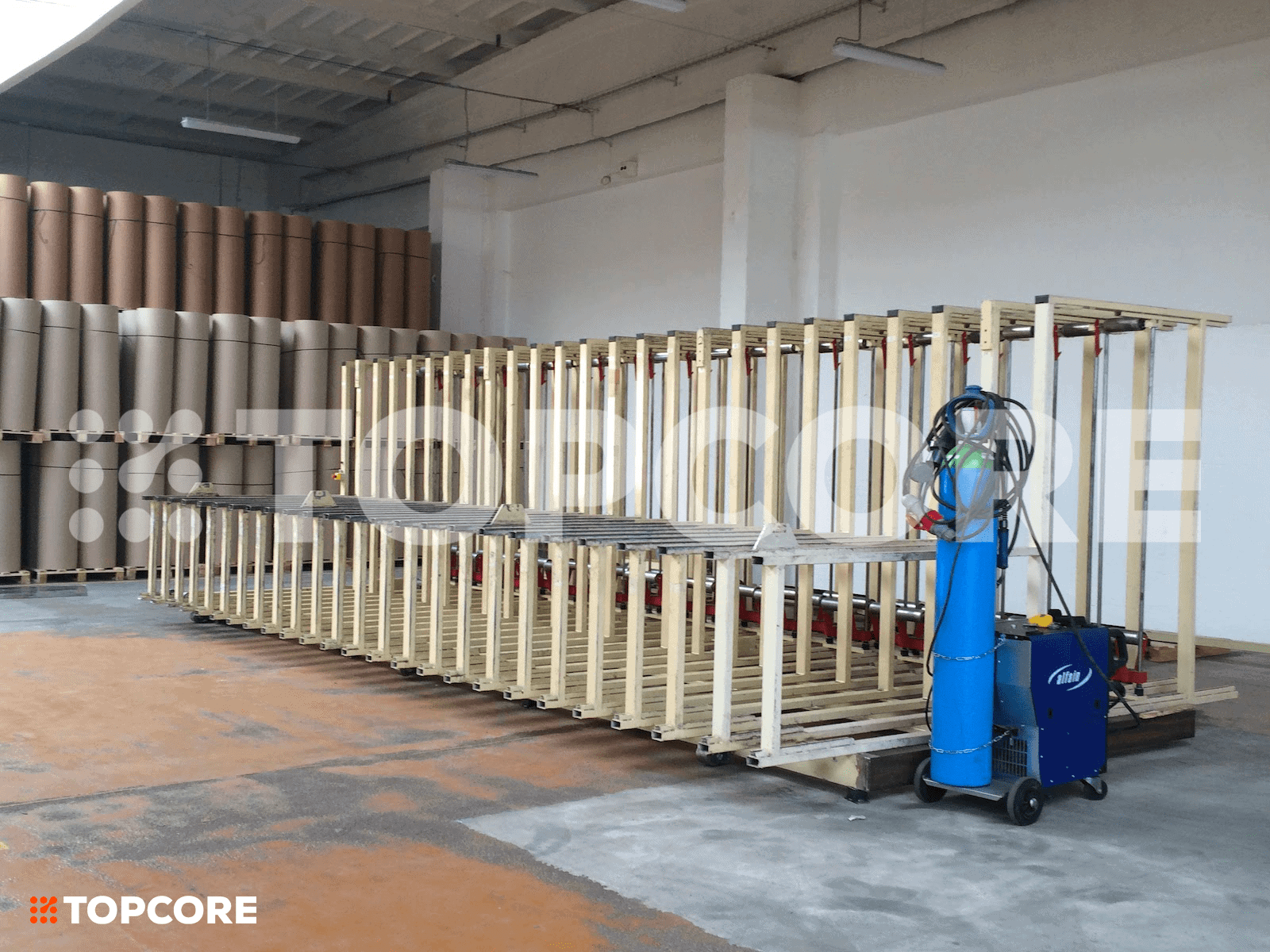

MANUFACTURE OF PAPER TUBES

Ecology, dextrin, sustainability

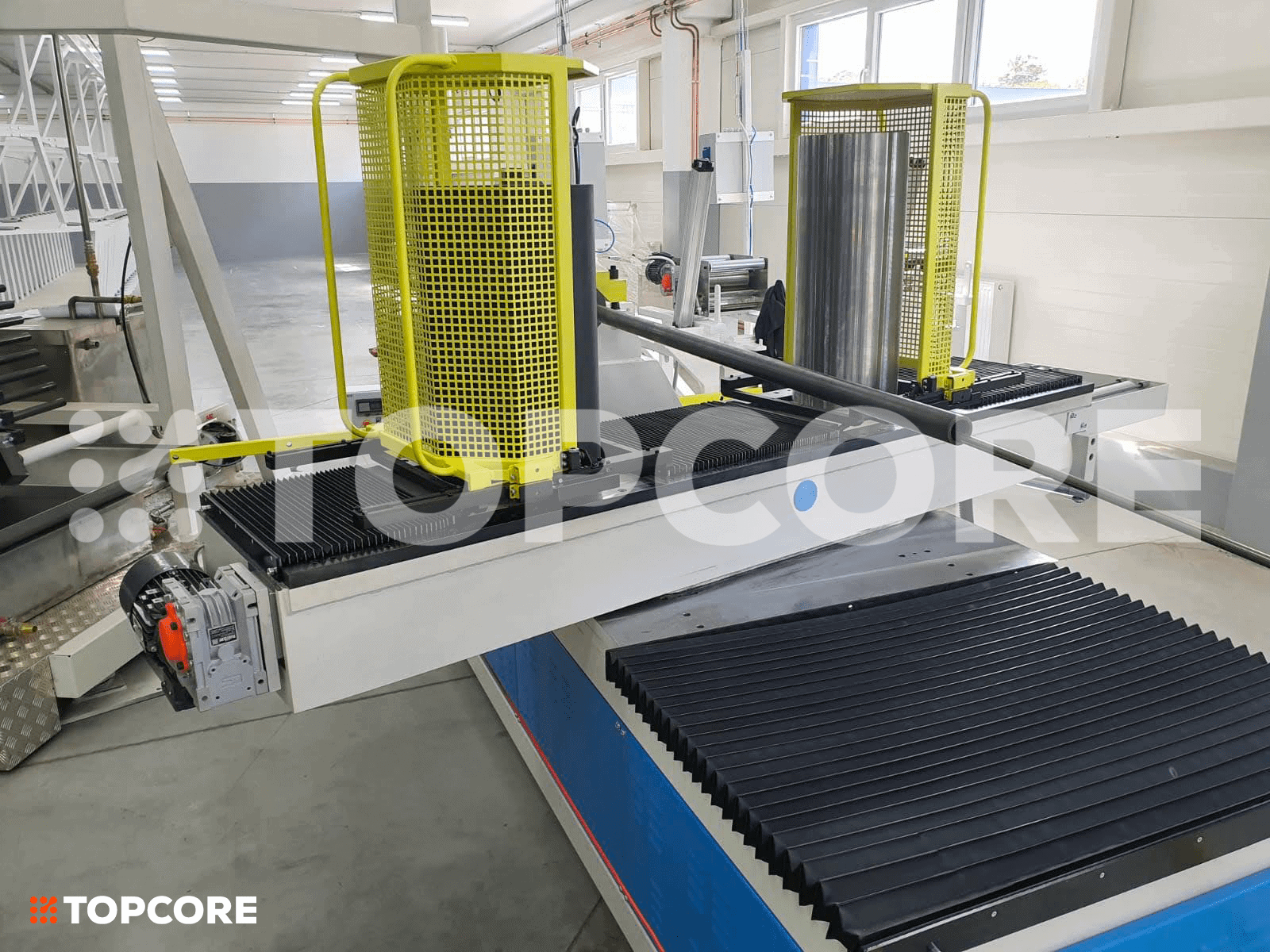

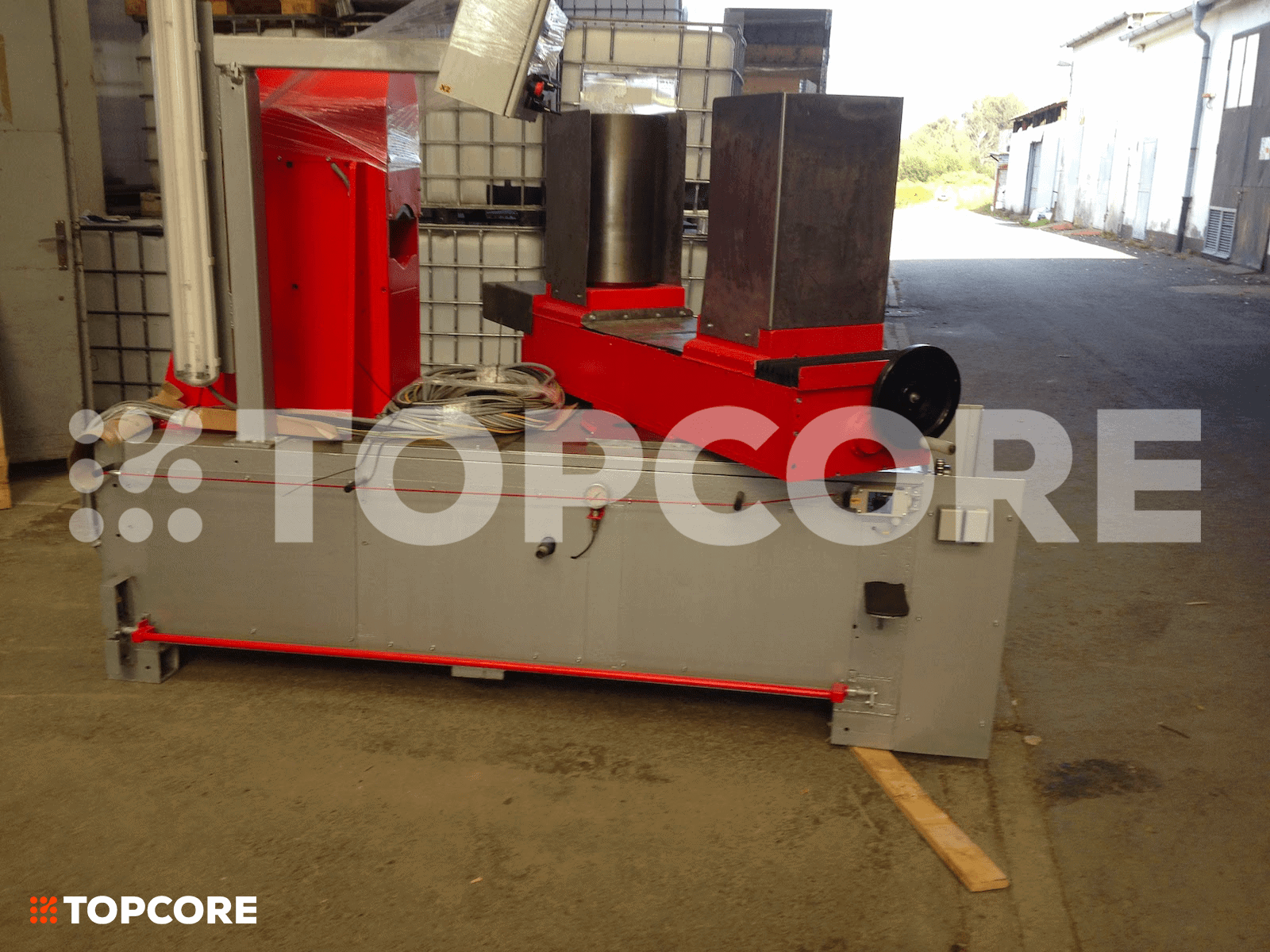

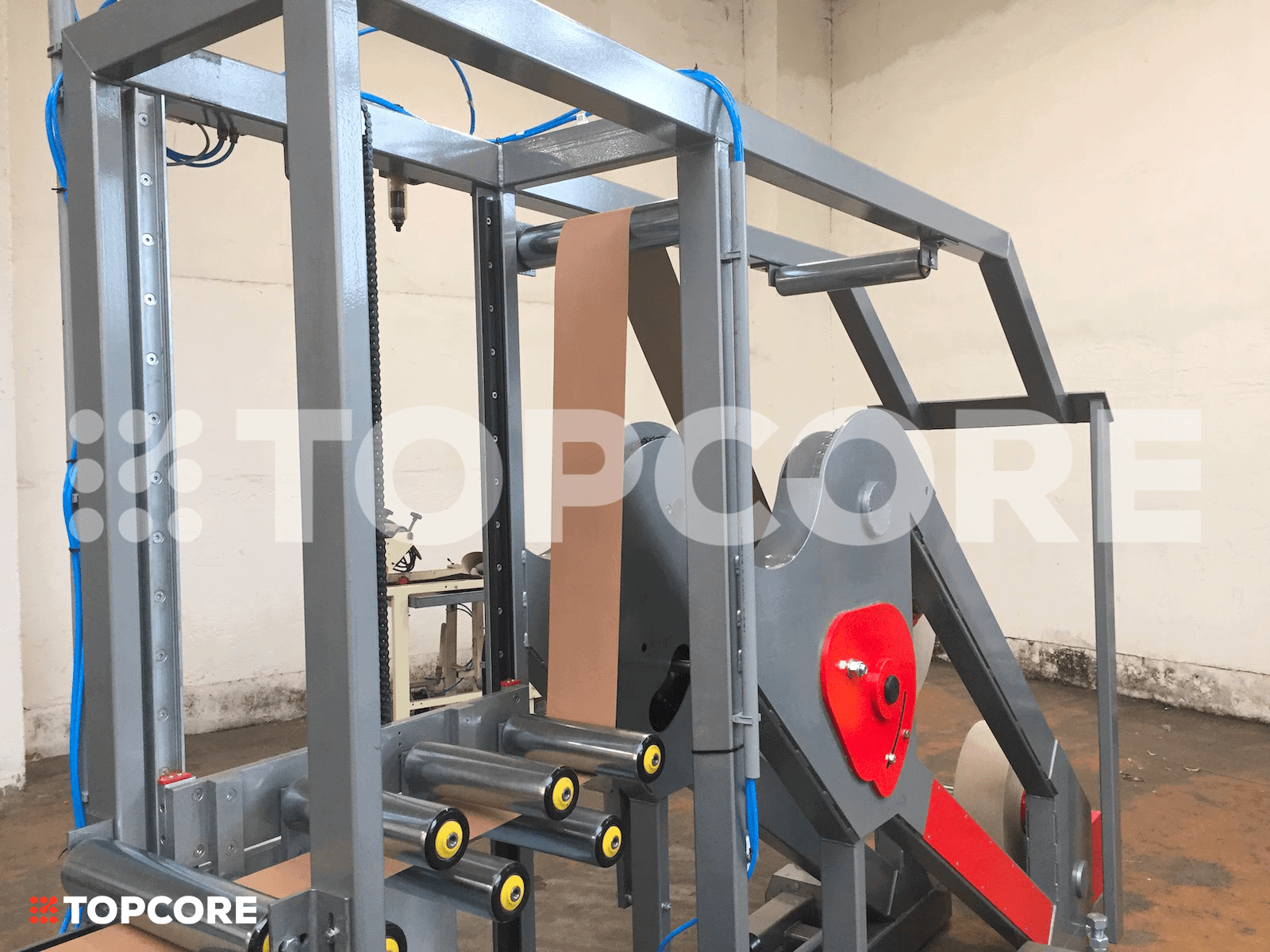

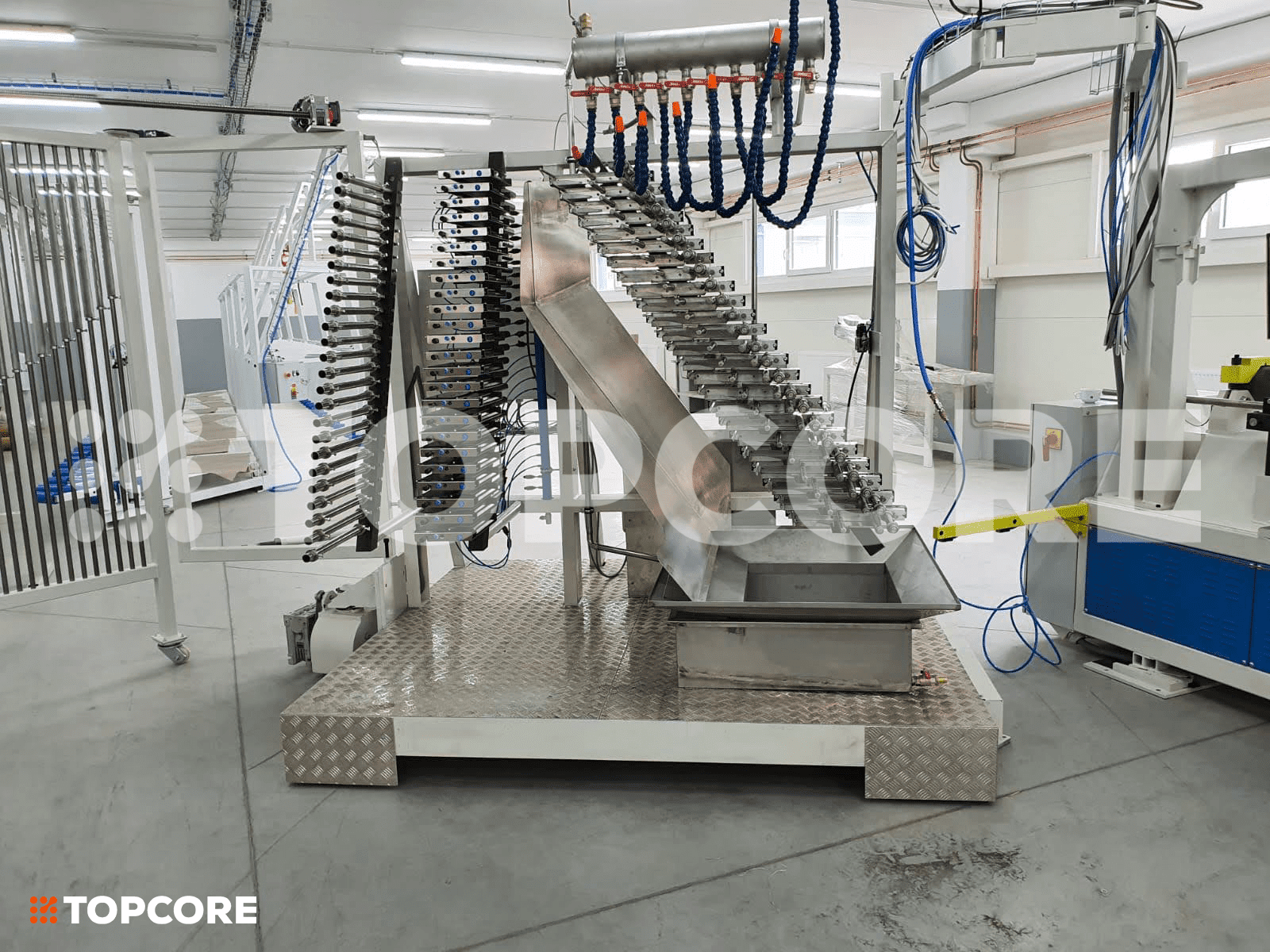

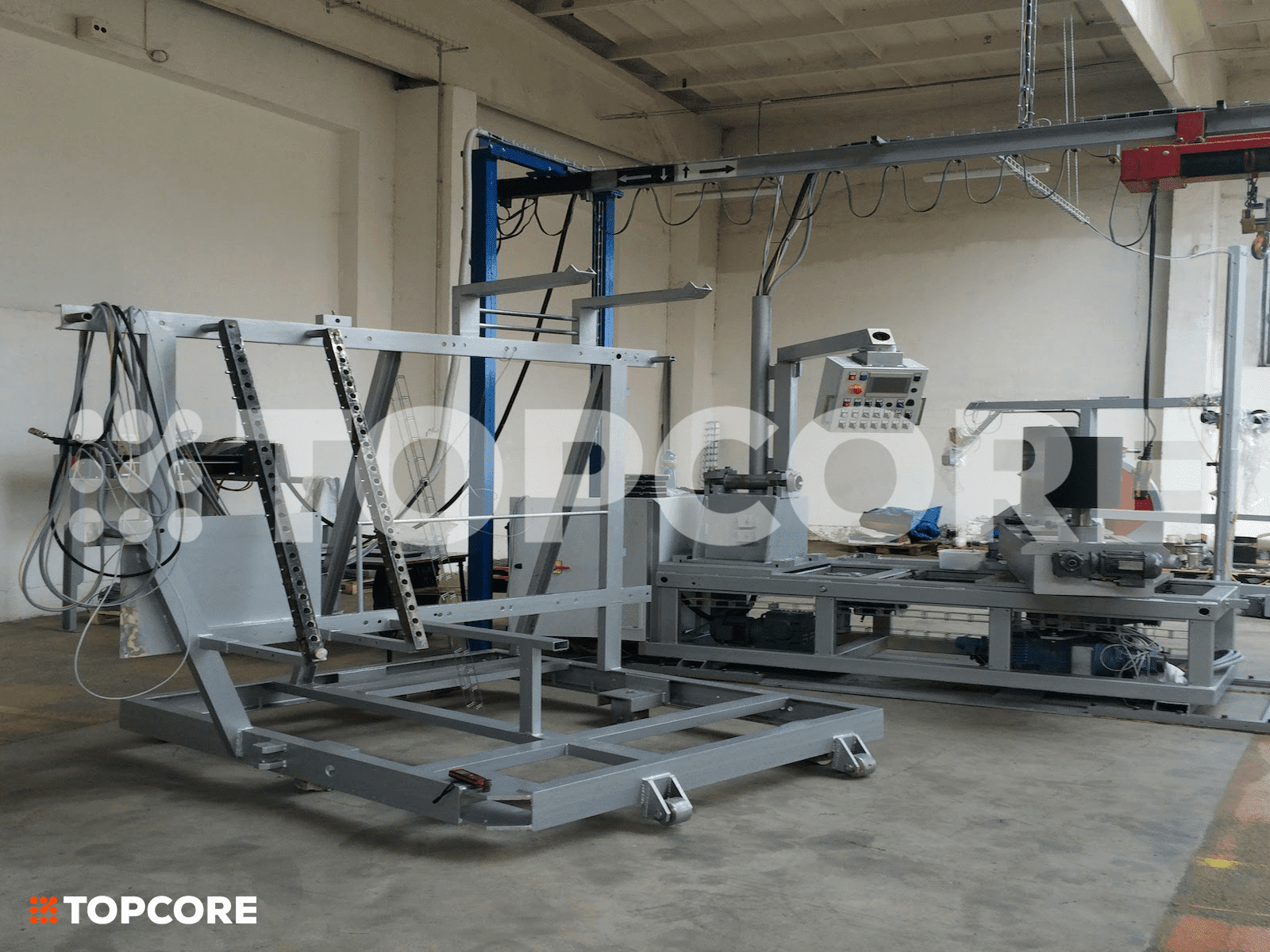

The glue station is another part of the entire production line. It includes a verticalizer, which allows the separation of the creel and the gluing section, and thus use less space in the production hall.

Stay tuned, more details are on the way.

The verticalizer allows us to “detach” the adhesive section from the stacker, thus saving space in the hall.

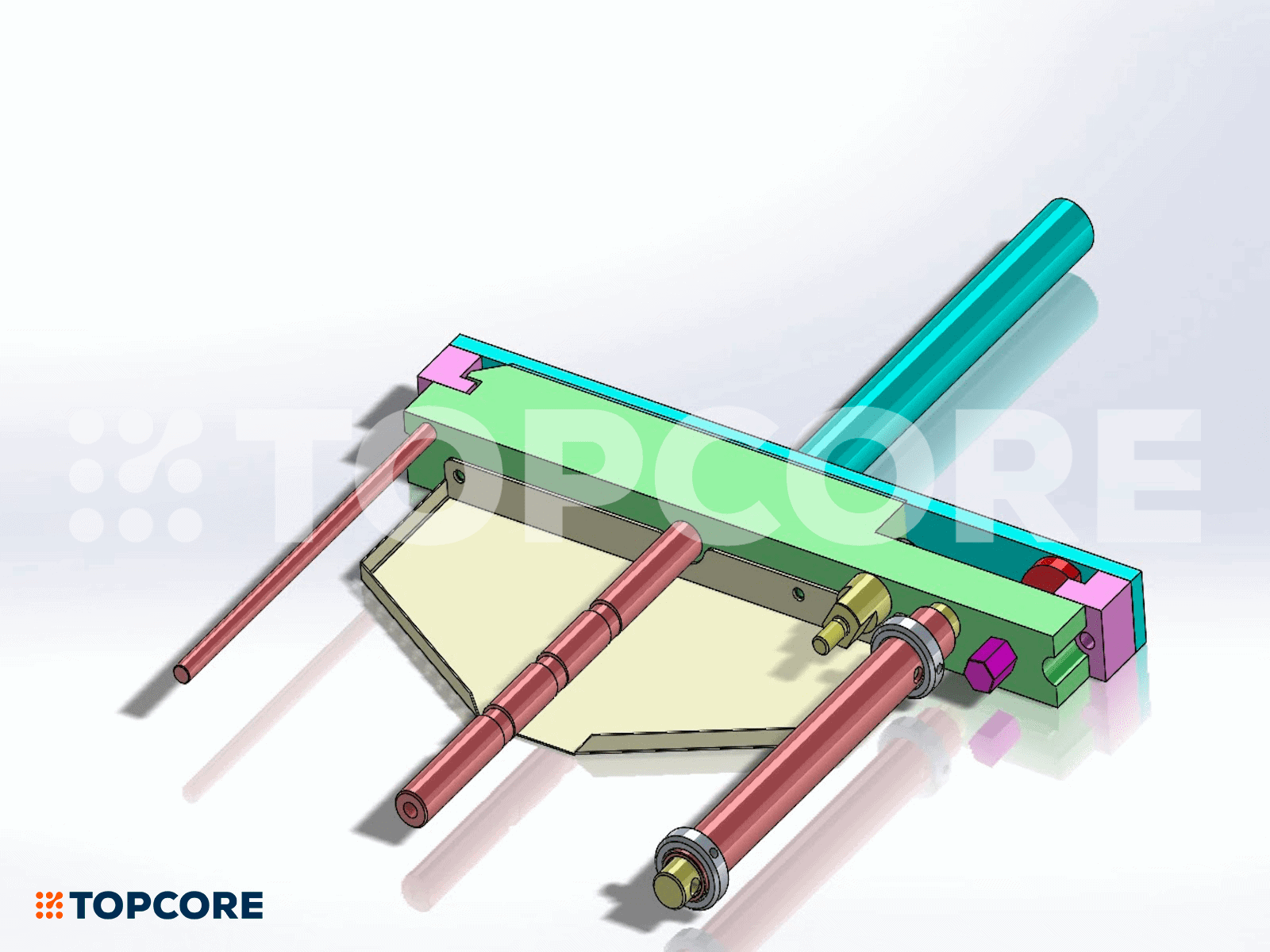

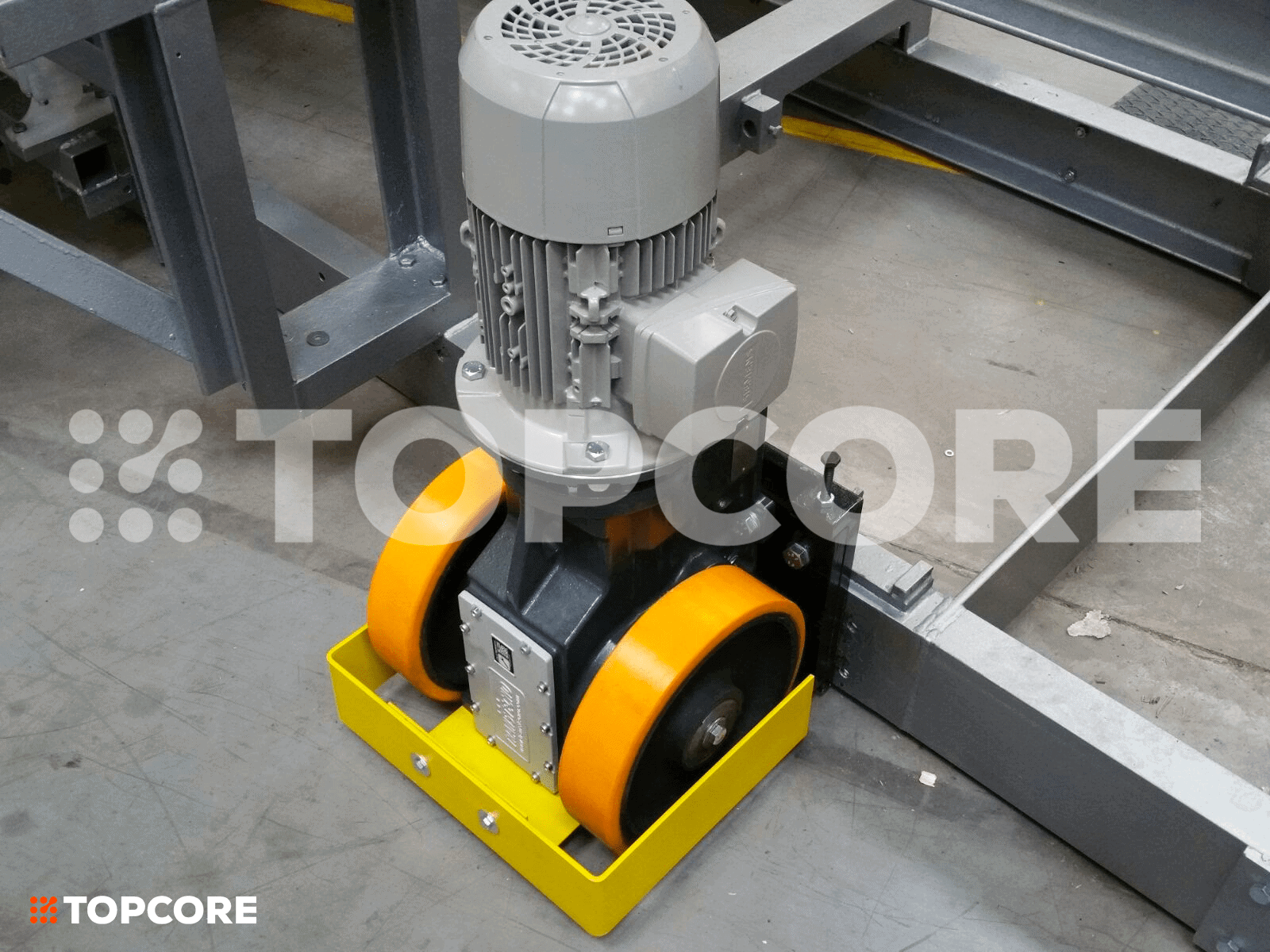

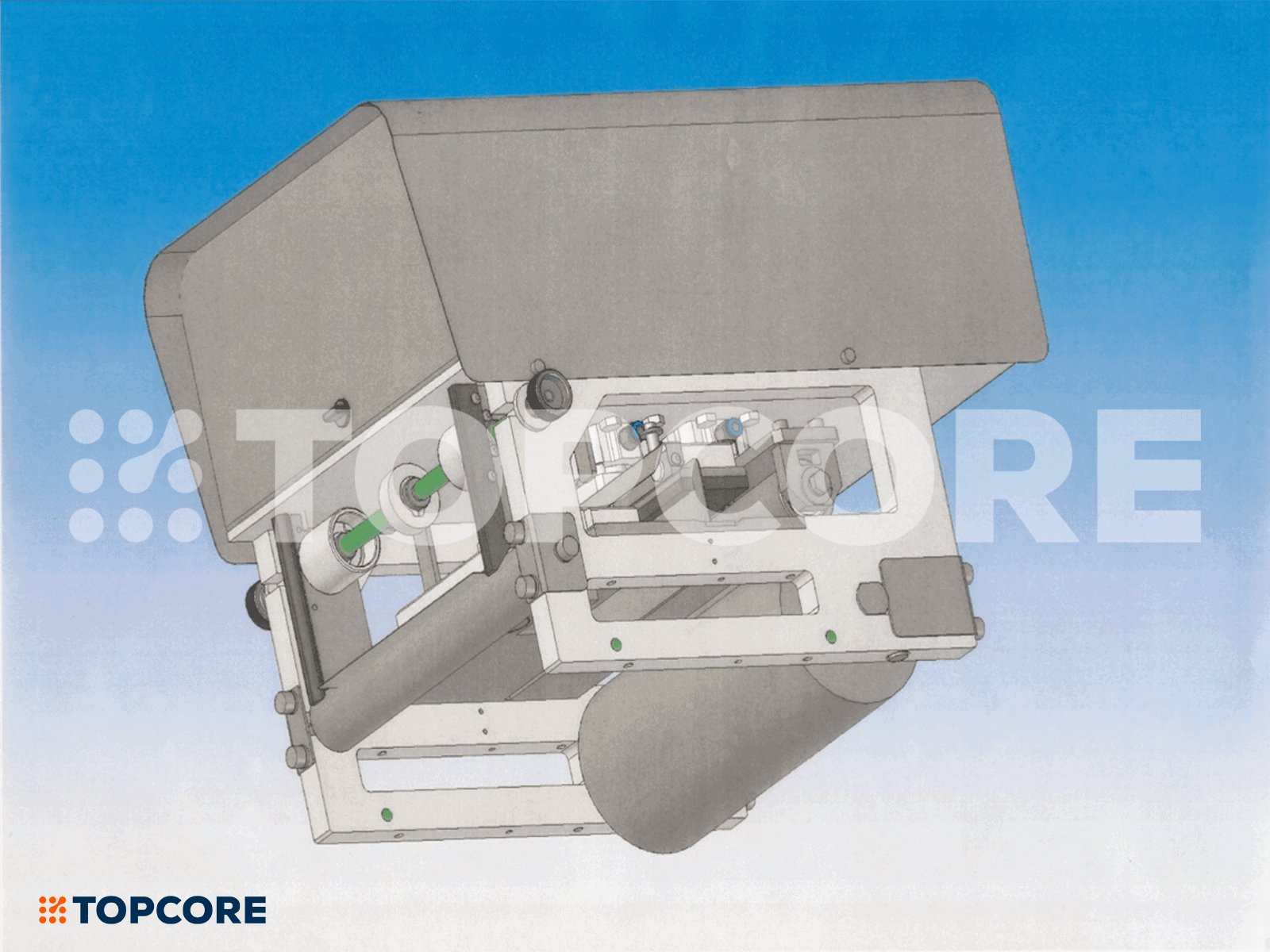

The drive including a travel wheel, which is dimensioned for the weight of the entire glue section for trouble-free movement or rotation when changing the size of the manufactured tube.

Stay tuned, more details are on the way.

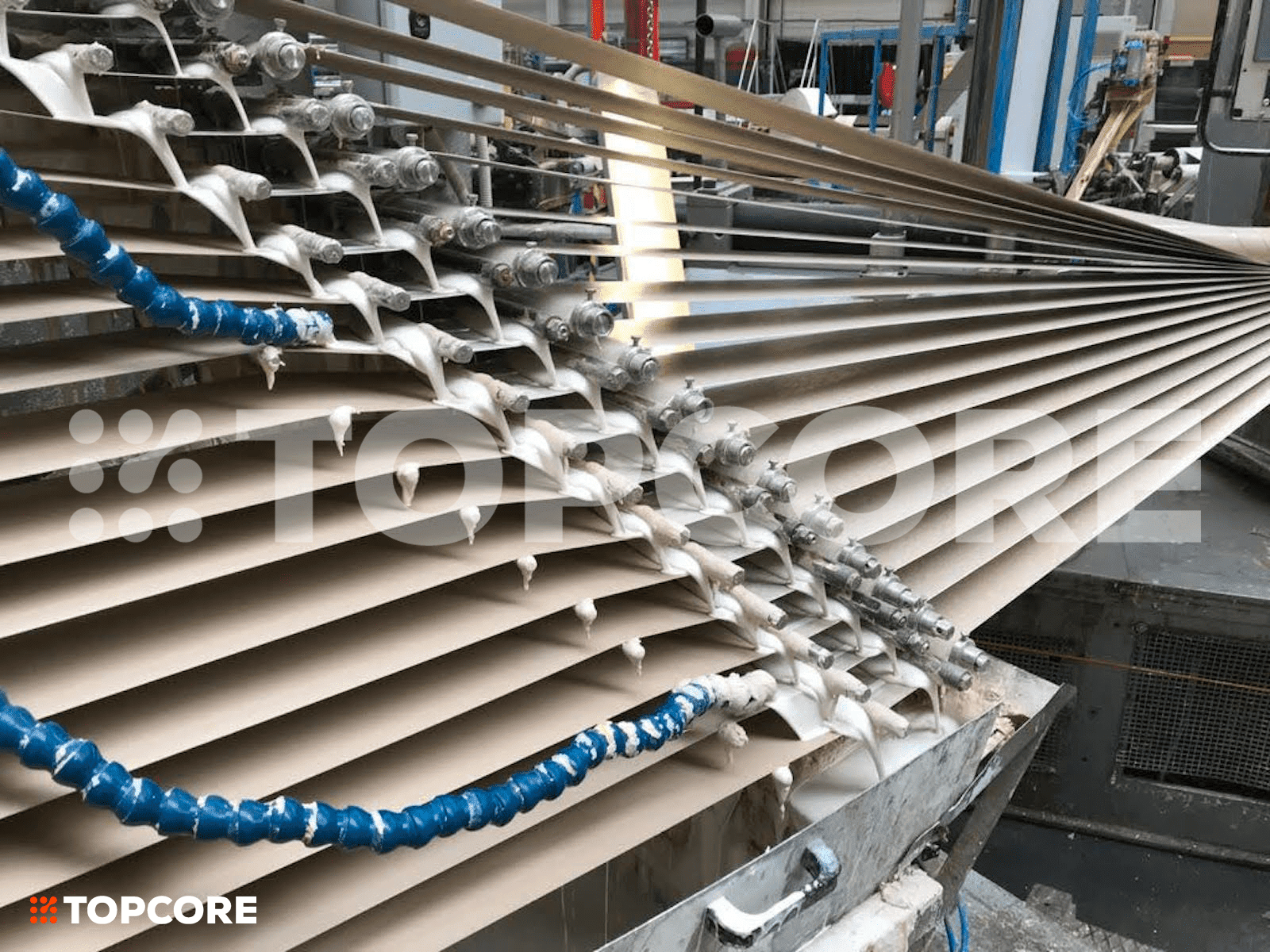

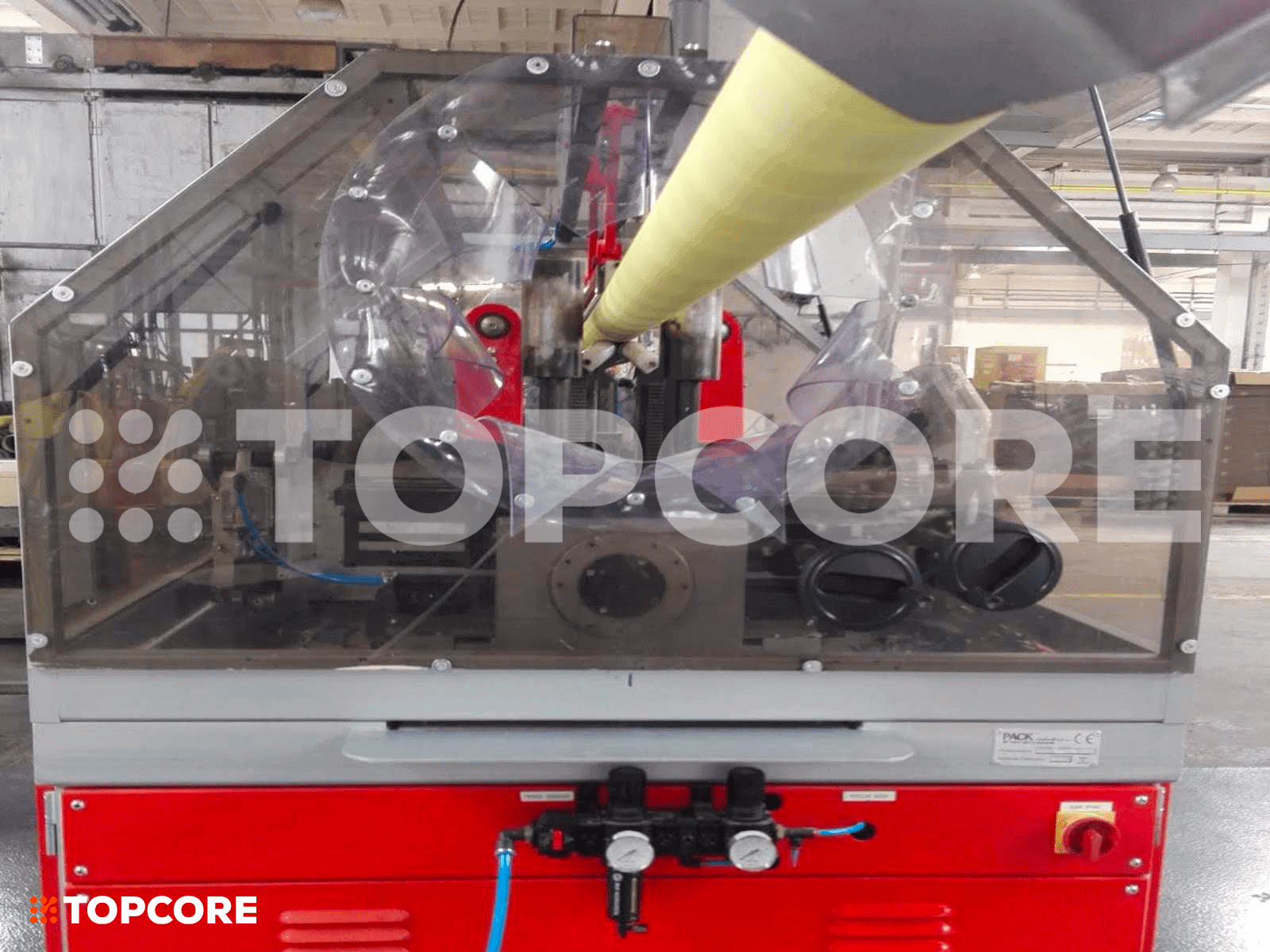

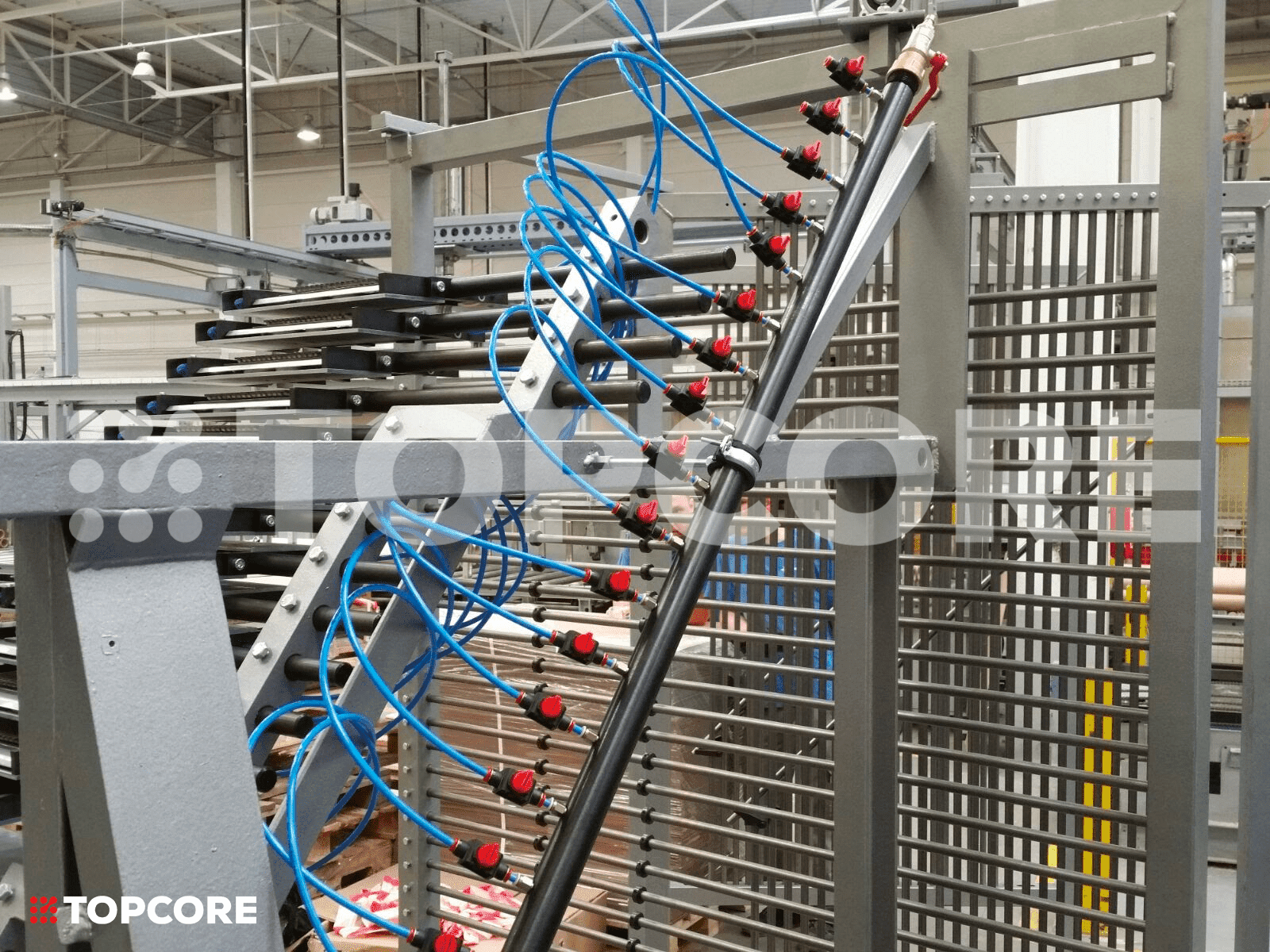

Pneumatic brakes provide the optimal tensioning solution for paper, ensuring a flawless adhesive application and a smooth winding onto the spindle. Elevate your process with precision and efficiency by choosing our pneumatic brakes.

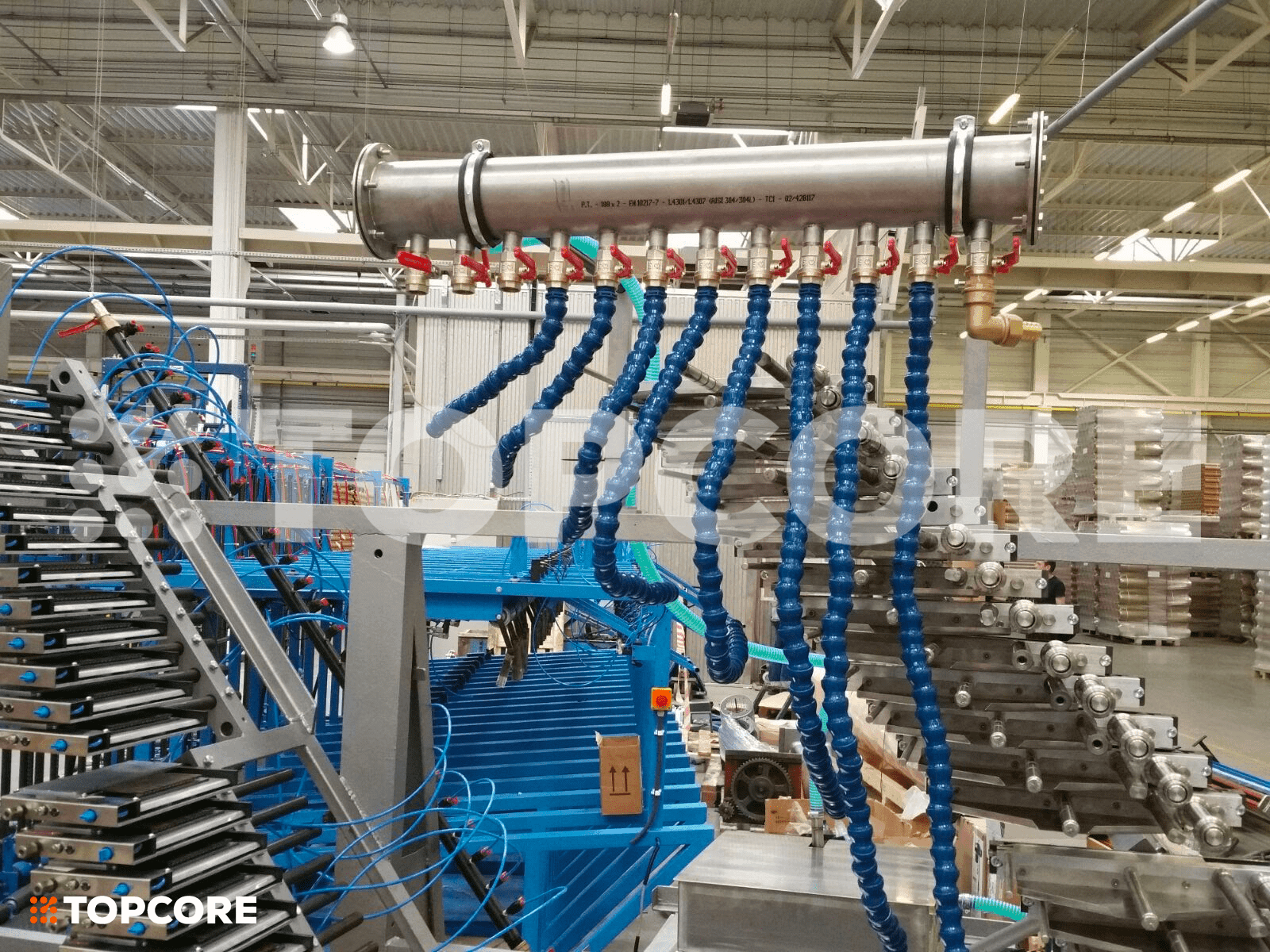

The glue distributor serves as a pre-supply of glue before application to the papers. Here the operator can regulate the flows to the individual papers.

The automatic splicer is used for quick connection of old and new paper. The old paper goes through a gluer, the new one is ready with adhesive tape for joining.

PAPER PROTECTIVE EDGES

Ecology, dextrin, sustainability

The glue station is another part of the entire production line. It includes a verticalizer, which allows the separation of the creel and the gluing section, and thus use less space in the production hall.

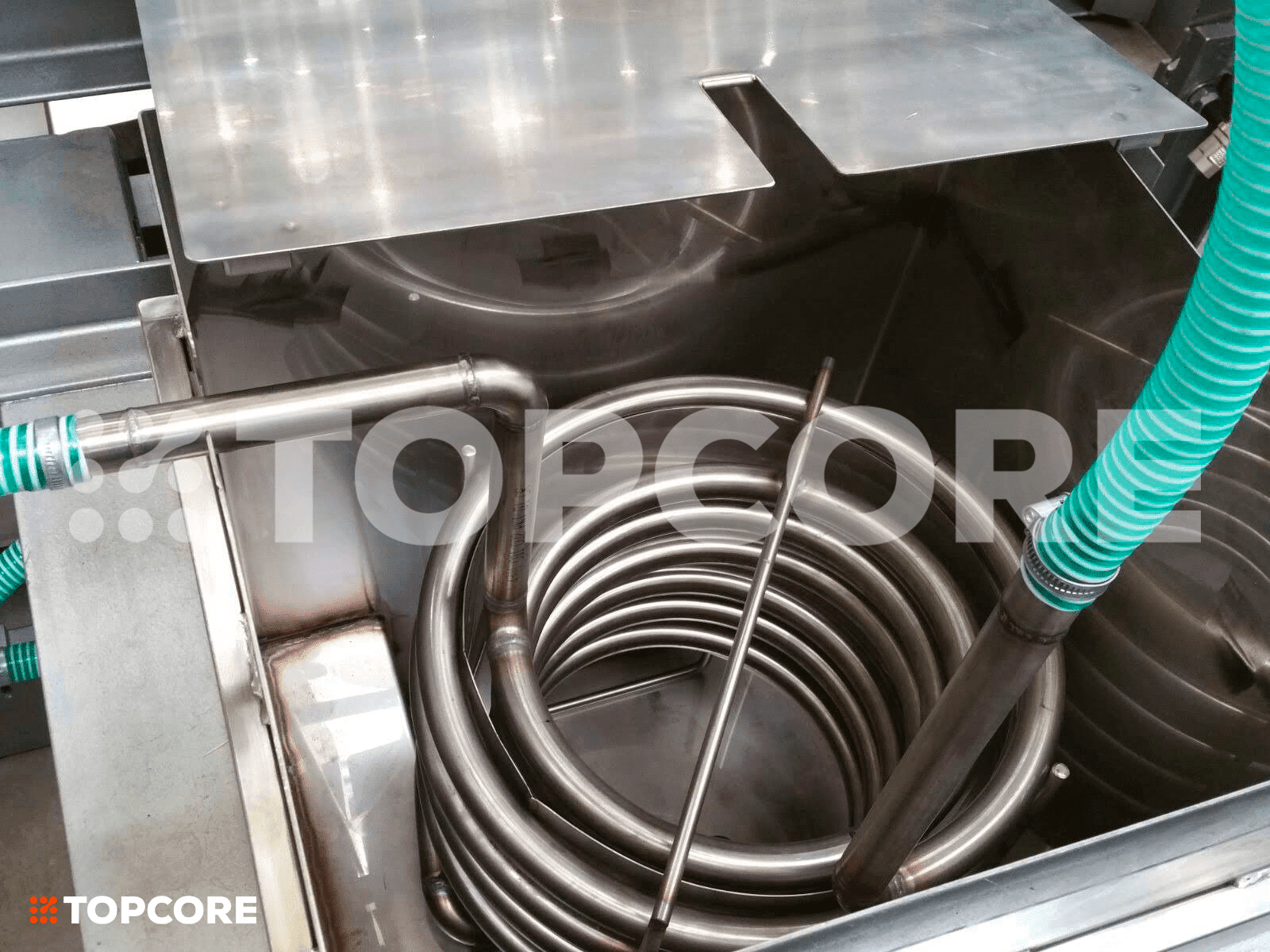

MIXING STATION

Ecology, dextrin, sustainability

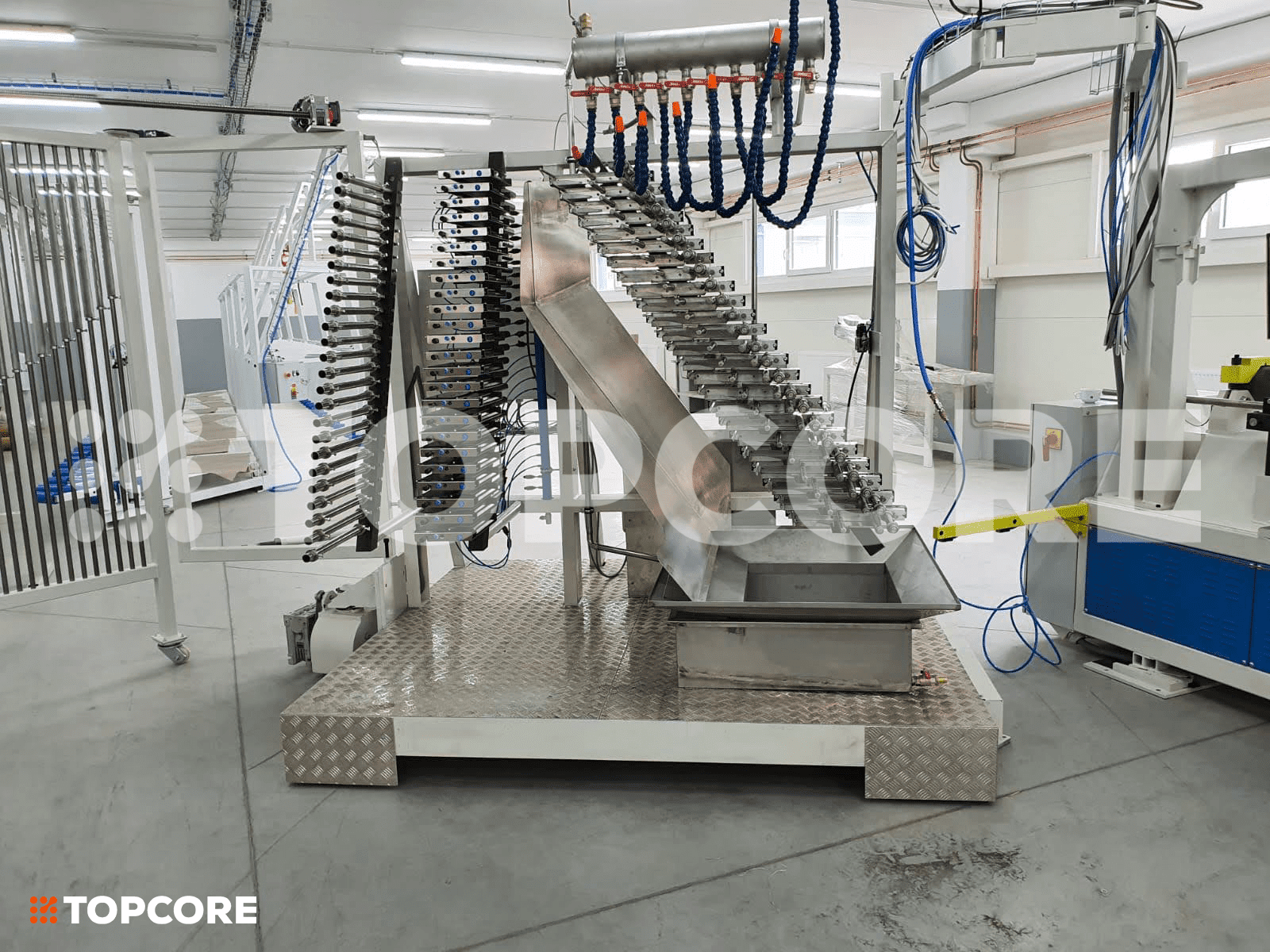

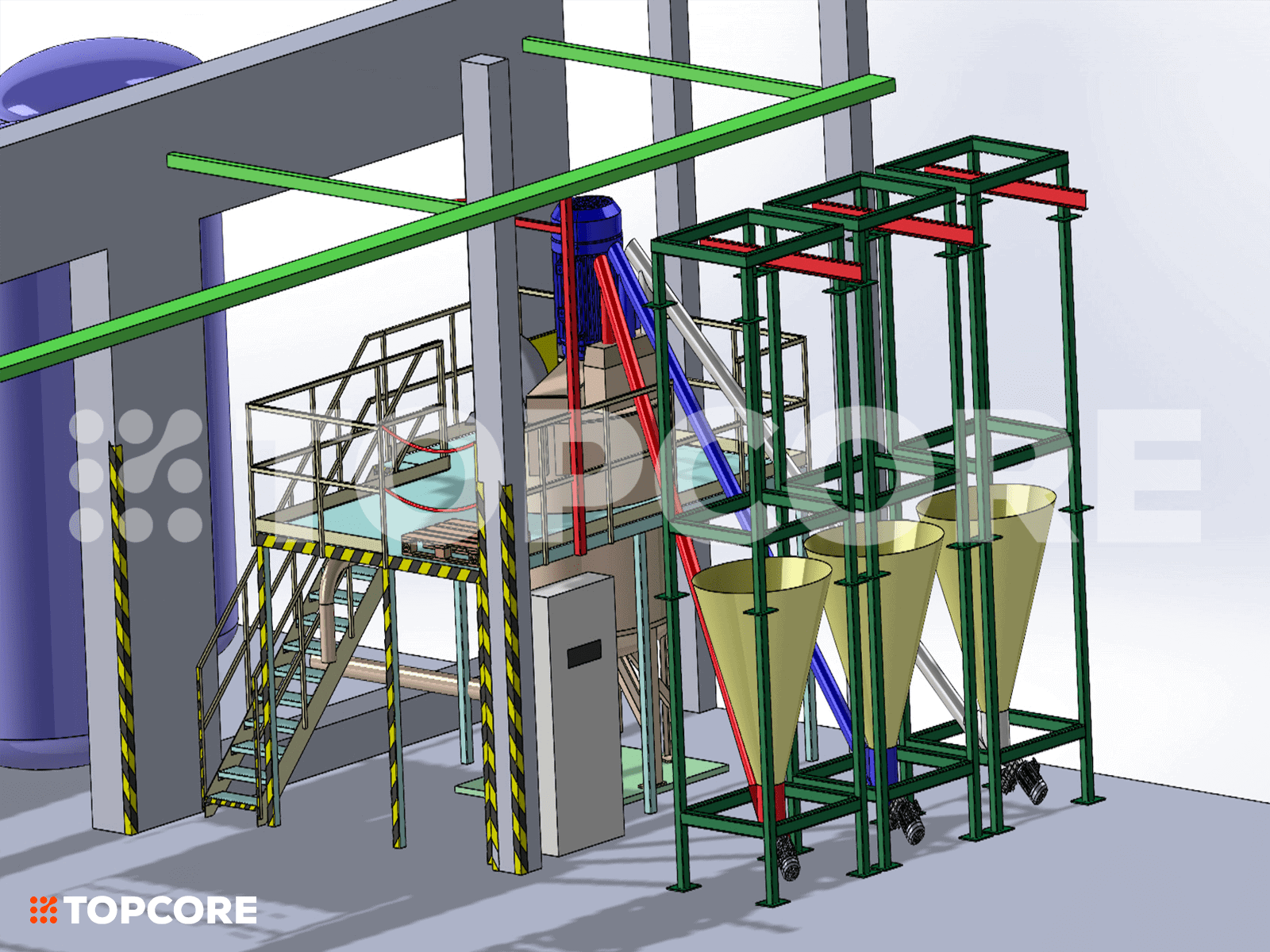

The mixing line is a complex device for the production of finished liquid glue from bulk raw materials. It can also be made from liquid raw materials.

RECONSTRUCTION

Ecology, dextrin, sustainability

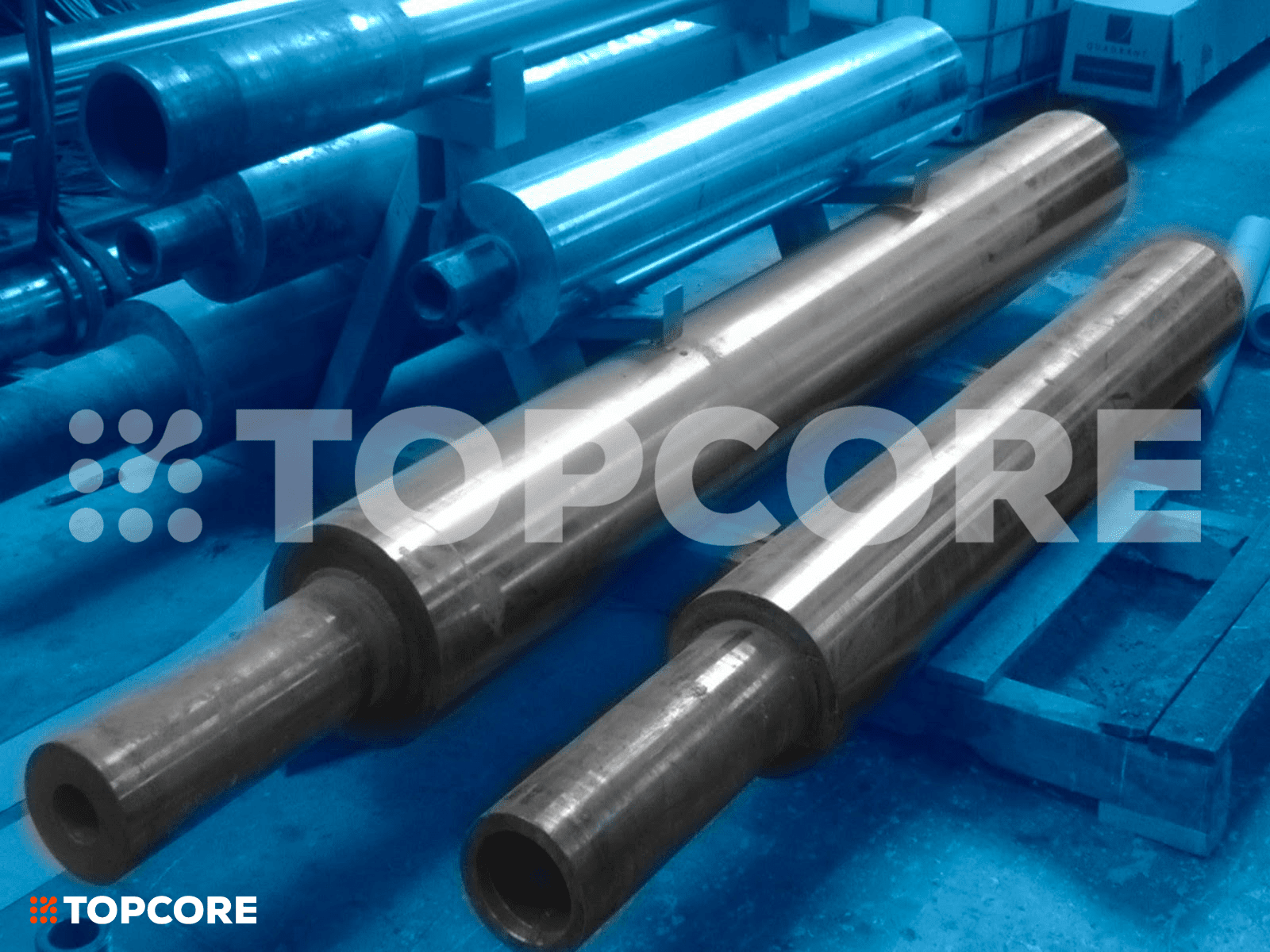

Is your glue station outdated? Let us rejuvenate it for you, complete with new brakes and wiper blade replacements.